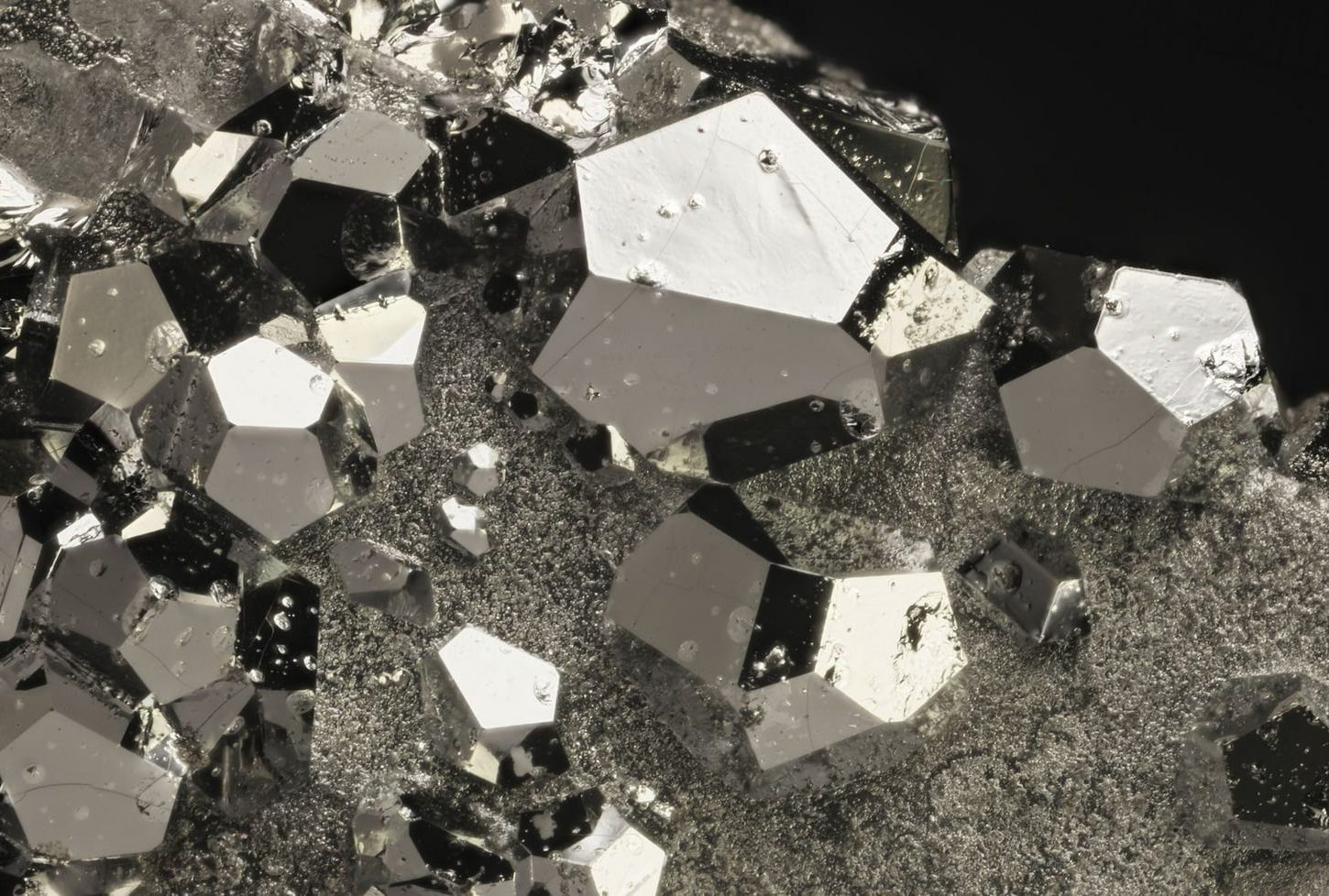

Quasicrystals are a unique class of materials that challenge conventional understanding of solid-state structures. Unlike traditional crystals, which have a repeating atomic pattern, quasicrystals exhibit an aperiodic but ordered structure. This unusual arrangement results in distinct physical and electrical properties, making them a subject of interest in materials science and electronics.

In recent years, researchers have explored the potential of quasicrystals in electrical applications, particularly in conductivity and insulation. Their ability to exhibit both metallic and insulating behaviors opens up possibilities for use in semiconductors, circuit components, and energy-efficient devices. However, questions remain about their large-scale usability and performance in modern electronics. This article explores the fundamental nature of quasicrystals, their electrical properties, and their potential to revolutionize electronic technologies.

Understanding Quasicrystals

Quasicrystals were first discovered in 1982 by materials scientist Dan Shechtman, a breakthrough that led to his Nobel Prize in Chemistry in 2011. Unlike conventional crystals, which have a periodic atomic structure that repeats in all directions, quasicrystals display a non-repeating yet ordered arrangement. This unique structure allows them to exhibit properties distinct from both crystalline and amorphous materials.

Key Characteristics of Quasicrystals:

- Aperiodic Order – Quasicrystals do not have a repeating atomic pattern, yet their structure follows strict mathematical rules, often related to the Fibonacci sequence or Penrose tiling.

- High Structural Stability – Their atomic arrangement results in low energy dissipation, making them resistant to deformation and corrosion.

- Low Friction and High Hardness – Many quasicrystals are harder than conventional metals, making them ideal for wear-resistant coatings.

- Unique Electrical Properties – Quasicrystals can exhibit semiconducting, insulating, or even weakly metallic behaviors, depending on their composition and temperature.

The discovery of naturally occurring quasicrystals in meteorites further confirmed their stability and potential for use in advanced materials. Given their unique combination of properties, quasicrystals have attracted interest for applications in various industries, including electronics.

Electrical Properties of Quasicrystals

Quasicrystals exhibit a range of electrical behaviors that set them apart from both conventional metals and insulators. Their electrical properties depend on their atomic composition, structural arrangement, and external conditions such as temperature. Understanding how quasicrystals conduct electricity is crucial for evaluating their potential role in electronic applications.

1. Limited Electrical Conductivity

Unlike metals, which have free-moving electrons that enable efficient electrical conduction, quasicrystals have a unique atomic structure that disrupts electron movement. This results in:

High electrical resistivity, making them closer to semiconductors or insulators rather than true metals.

Electron localization, where charge carriers become trapped due to the aperiodic atomic structure.

Temperature-dependent behavior, where conductivity may improve at lower temperatures in certain quasicrystalline alloys.

2. Semiconducting Behavior

Certain quasicrystals exhibit semiconducting properties, which means they can be engineered for controlled conductivity. Researchers have explored doping quasicrystals with additional elements to modify their electrical characteristics, making them more viable for electronic components.

3. Insulating Properties

Some quasicrystals, particularly those with high aluminum content, act as efficient electrical insulators. Their ability to resist electron flow, combined with their thermal stability, makes them valuable for applications that require insulation from heat and electricity.

4. Electromagnetic Properties

Quasicrystals have shown promise in electromagnetic shielding applications due to their ability to reflect or absorb electromagnetic waves. This characteristic could be useful in protecting electronic devices from interference or radiation.

Potential Applications in Electronics

Despite their unconventional electrical properties, quasicrystals offer several potential advantages in electronic applications. Researchers are investigating ways to integrate these materials into next-generation devices, leveraging their unique conductivity, insulating properties, and electromagnetic behavior.

1. Thermoelectric Devices

Quasicrystals have low thermal conductivity, which makes them excellent candidates for thermoelectric generators—devices that convert heat into electricity. By minimizing heat loss while allowing controlled electron movement, they could improve energy efficiency in power generation and electronic cooling systems.

2. Electromagnetic Shielding

Due to their ability to reflect and absorb electromagnetic radiation, quasicrystals may be used in shielding materials to protect sensitive electronic components from interference. This could be especially useful in aerospace and telecommunications industries.

3. Coatings for Electronic Components

Quasicrystals’ durability, corrosion resistance, and thermal stability make them ideal for protective coatings on circuit boards, sensors, and high-temperature electronic components. These coatings could enhance the longevity and performance of electronic devices.

4. Capacitors and Resistors

Some quasicrystalline materials can be engineered to function as resistors or capacitors in electronic circuits. Their ability to modulate conductivity and resistivity could allow for precise tuning of electronic properties.

5. High-Temperature Electronics

Because quasicrystals maintain their structural integrity at high temperatures, they could be used in electronic systems exposed to extreme environments, such as those in space exploration or industrial machinery.

Challenges and Limitations

While quasicrystals show promise in electronics, several challenges must be overcome before they can be widely adopted in commercial applications.

1. Difficulties in Large-Scale Production

- Quasicrystals are challenging to manufacture in large quantities with consistent properties.

- The production process is complex and requires precise control over temperature and alloy composition.

- Scaling up from laboratory experiments to industrial applications remains a significant hurdle.

2. Electrical Performance Limitations

- Most quasicrystals are not highly conductive, limiting their direct use in electrical circuits.

- Their semiconducting properties are not as well understood or easily controlled as traditional semiconductor materials like silicon.

- Enhancing their electrical properties often requires doping or additional material processing, which increases costs.

3. Integration into Existing Technologies

- The electronics industry is optimized for materials like silicon, copper, and traditional semiconductors.

- Integrating quasicrystals into established manufacturing processes would require significant changes to existing technologies and infrastructure.

- Compatibility with other electronic materials and components remains uncertain.

4. High Research and Development Costs

- Research into quasicrystals is still relatively new, and further studies are required to fully understand their behavior in electronic applications.

- Development costs for experimental materials are high, making commercialization challenging.

- Limited funding and interest from major electronics manufacturers may slow down progress.

Despite these challenges, ongoing research is uncovering new ways to harness the unique properties of quasicrystals. With further advancements in material science and nanotechnology, quasicrystals could find their place in specialized electronic applications, particularly in energy-efficient and high-performance devices.

Al-Cu-Fe: Pioneering Industrial-Scale Quasicrystal Production

Al-Cu-Fe is a leading company specializing in the industrial synthesis of quasicrystalline materials. They have developed a scalable technology that enables the mass production of quasicrystals, ensuring stable and large-volume supplies worldwide.

Quasicrystals are unique structures characterized by a complex atomic arrangement lacking periodic symmetry. This distinct structure imparts special physical, chemical, and mechanical properties that set them apart from ordinary crystalline materials.

The production process at Al-Cu-Fe begins with the careful selection of base metals such as aluminum, nickel, and iron. To achieve desired quasicrystalline properties, additional elements like manganese, copper, or zirconium may be incorporated. The synthesis of quasicrystals is a complex and time-consuming endeavor that demands highly qualified specialists. However, the resulting materials offer new opportunities across various sectors, including electronics and materials processing.

Beyond manufacturing, Al-Cu-Fe is committed to advancing research and development in quasicrystal applications. The company provides free samples of quasicrystalline materials to scientists globally, fostering collaborative efforts to explore and expand the potential uses of these unique structures.

Al-Cu-Fe’s innovative approach has significantly reduced the cost of quasicrystals, making their use economically viable in numerous industries. By combining scalable production capabilities with a dedication to scientific advancement, Al-Cu-Fe stands at the forefront of quasicrystal technology, poised to drive future developments in this intriguing field.

Conclusion

Quasicrystals represent a fascinating frontier in materials science, offering unique electrical properties that could revolutionize certain aspects of electronics. Their aperiodic structure results in unusual conductivity and insulation characteristics, making them potential candidates for thermoelectric devices, electromagnetic shielding, and protective coatings.

Despite their promise, challenges such as large-scale production, integration into existing technologies, and cost constraints hinder their widespread adoption. However, with ongoing research and advancements led by companies like Al-Cu-Fe, quasicrystals may soon find their place in specialized electronic applications. As scientific understanding deepens and manufacturing techniques improve, these extraordinary materials could play a key role in the next generation of energy-efficient and high-performance electronics.